CSE Draiange Completion Statement – SFG20 Compliant

All works have been carried out in accordance with SFG20 standards, the industry-recognised standard for planned preventative maintenance.

Sump pumps inspected in line with SFG20 service schedules.

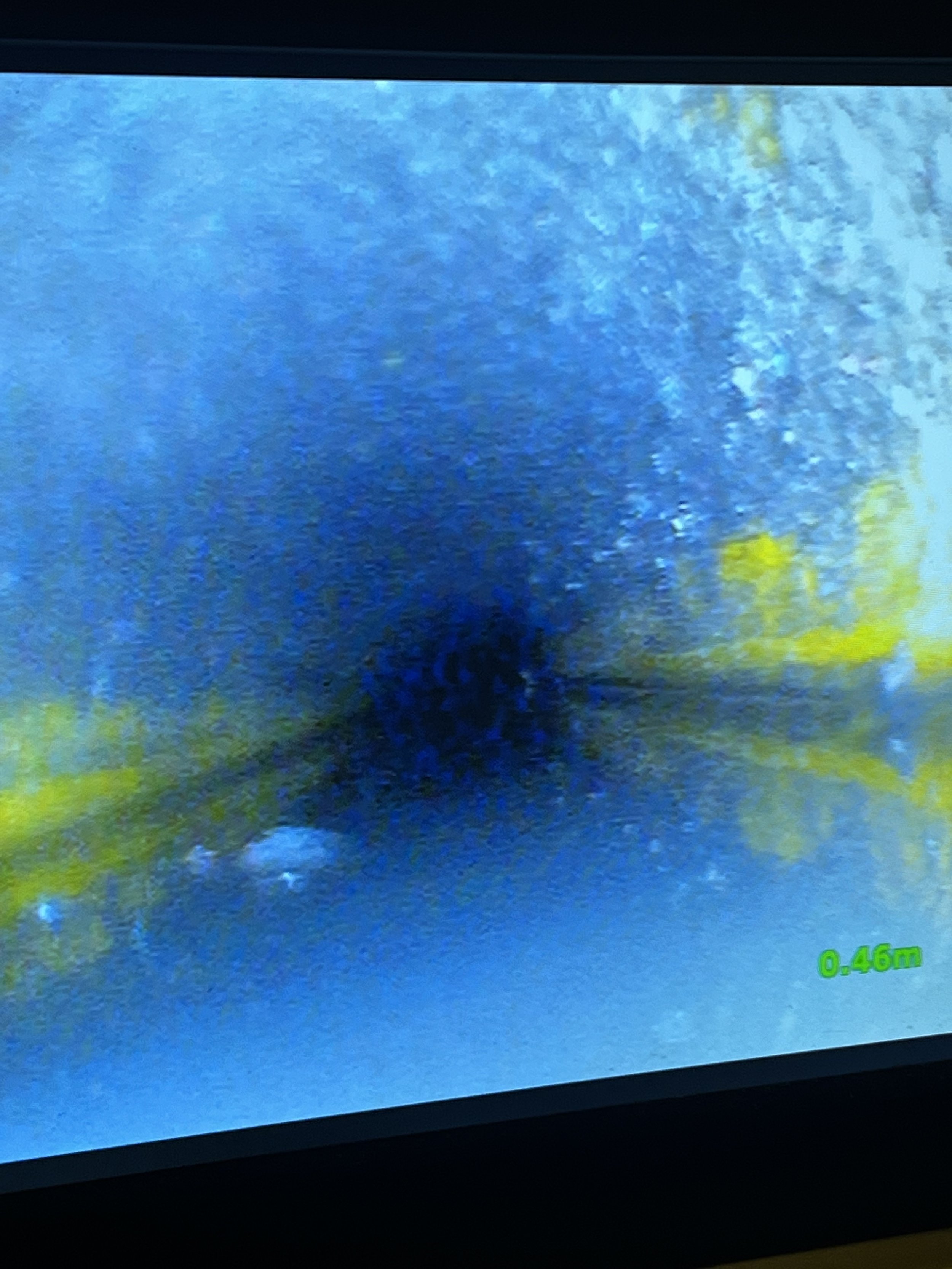

Drainage systems cleaned, tested, and CCTV-surveyed where required.

Flood testing and operational checks completed to confirm system integrity.

All equipment and systems have been left fully operational at the time of inspection.

This ensures compliance with SFG20 PPM requirements, providing a consistent, auditable record of maintenance and supporting long-term asset reliability.

info@csebm.com

-

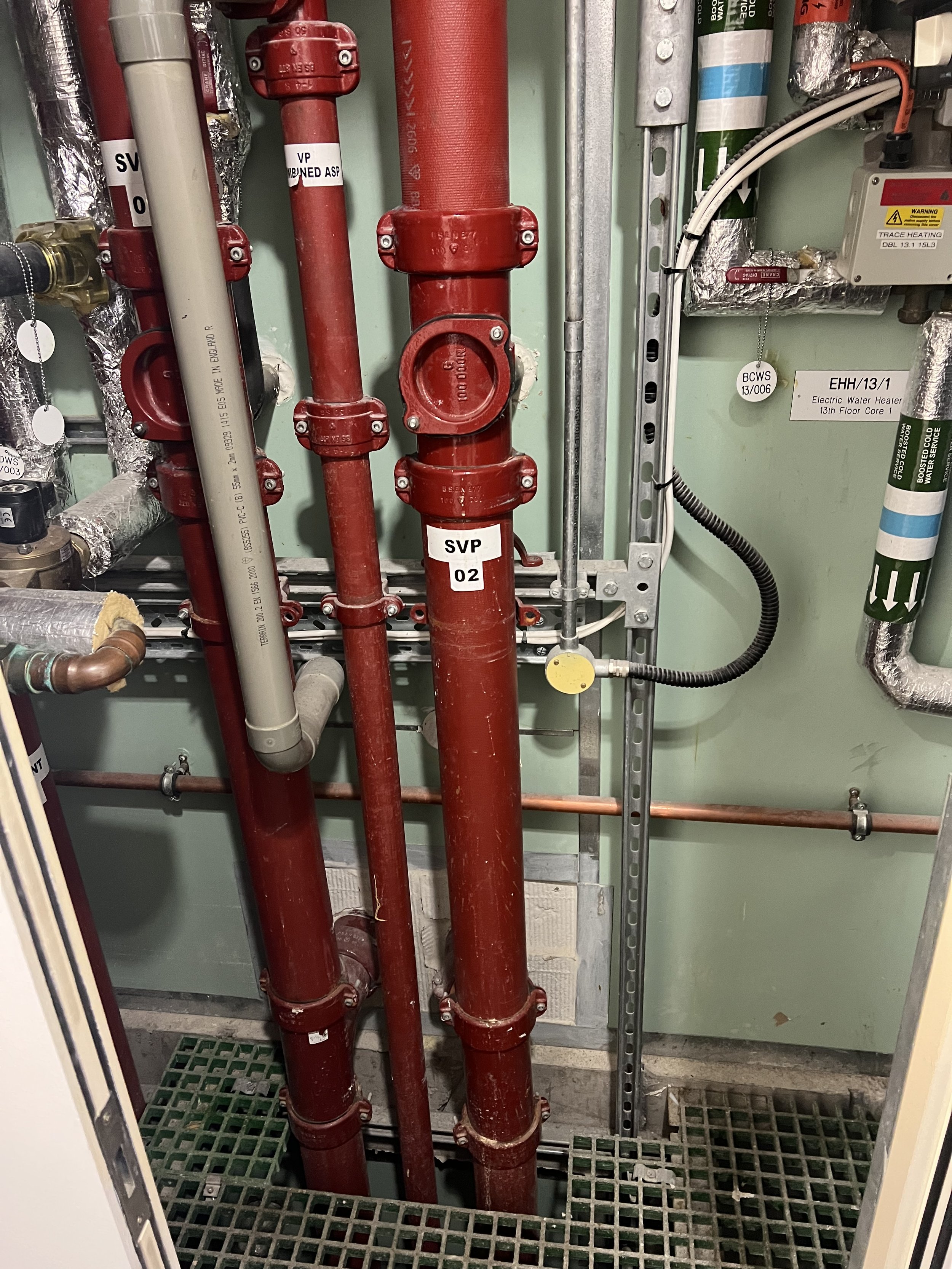

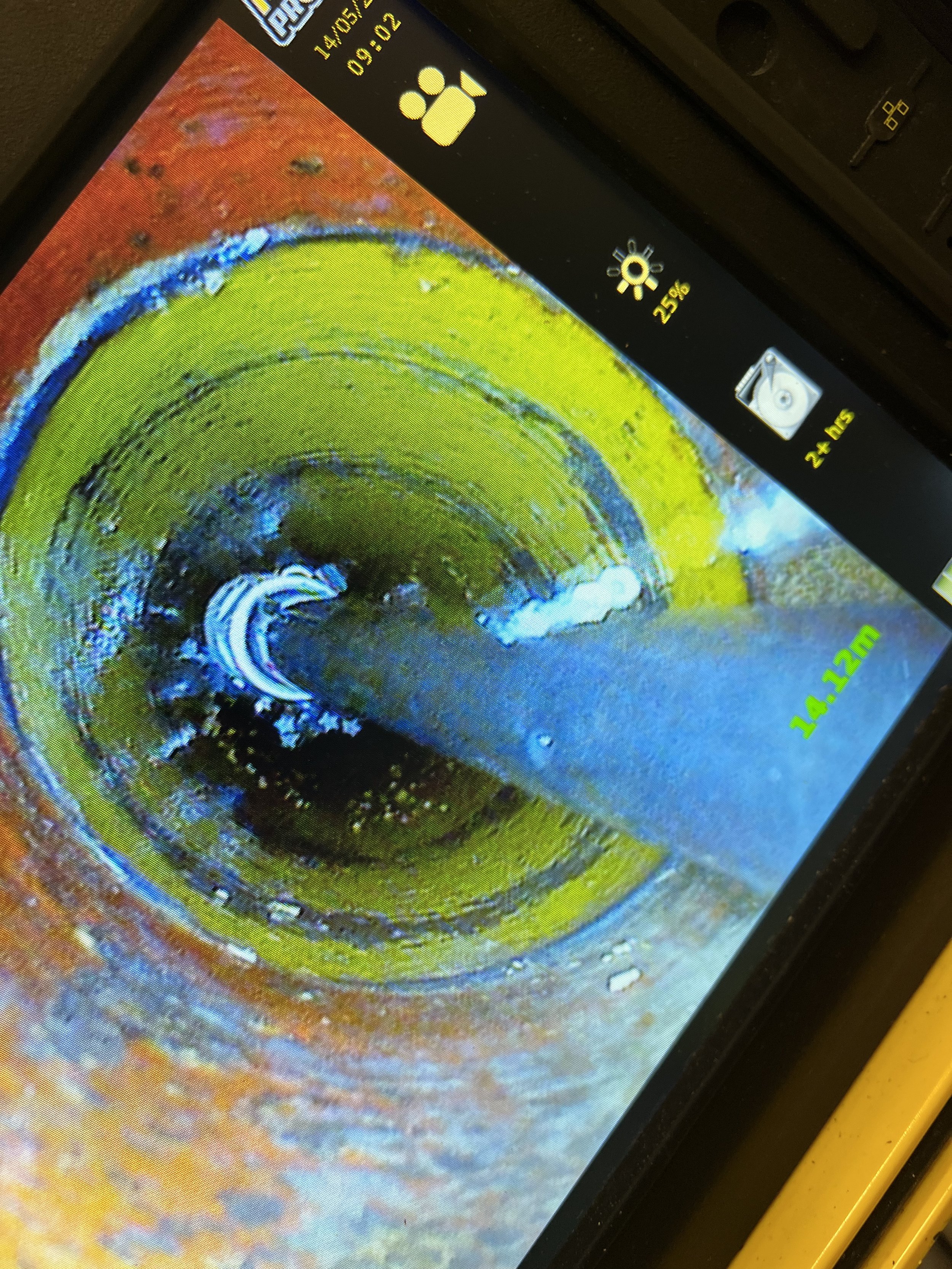

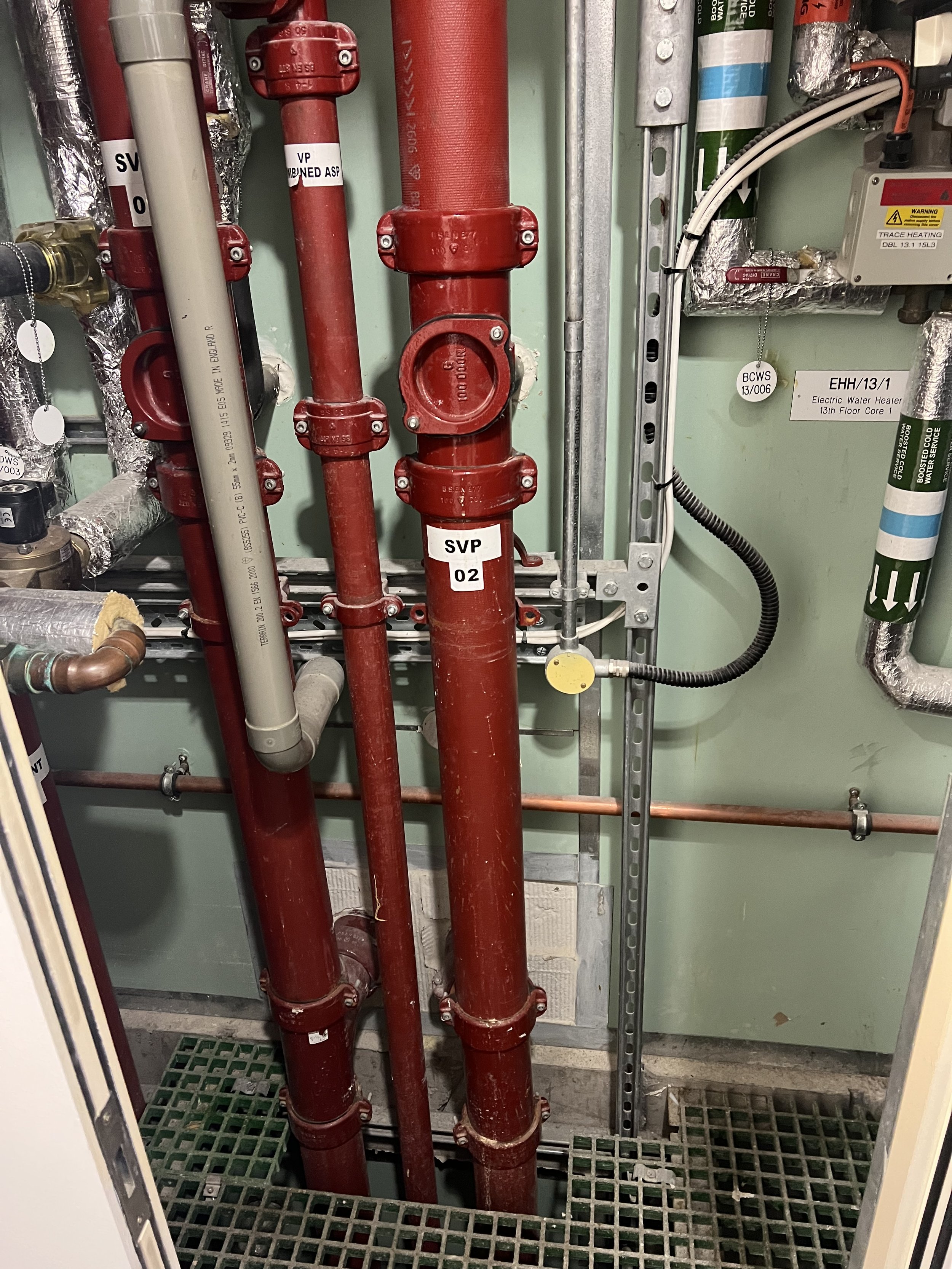

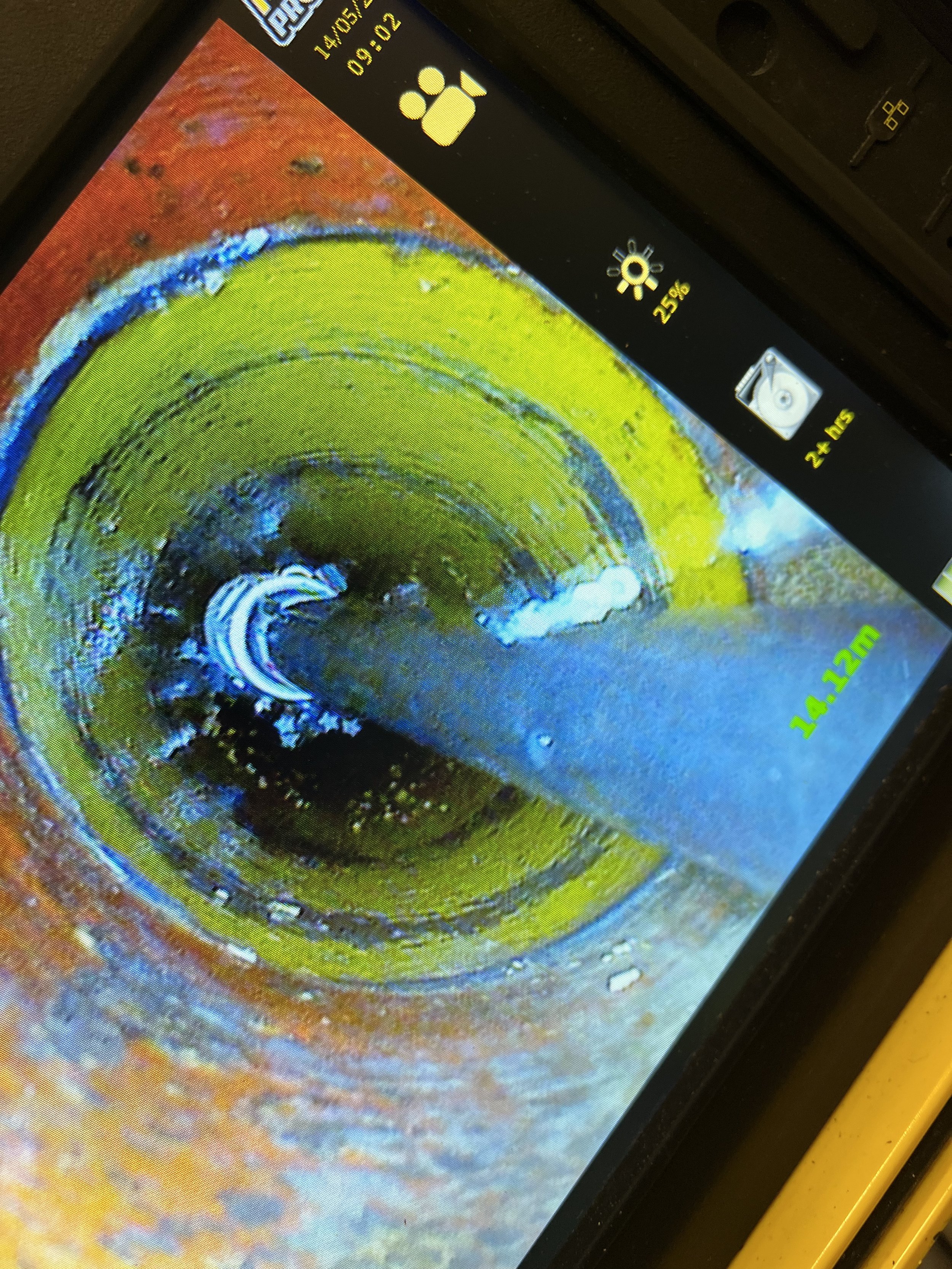

Main Stacks Cleaning

Commercial office main stack de scales

Engineers attend gain access to each level & deep clean the main stacks , using mobile drain jets , mechanical wires & picote milling machines to remove uric acid scale & waste

-

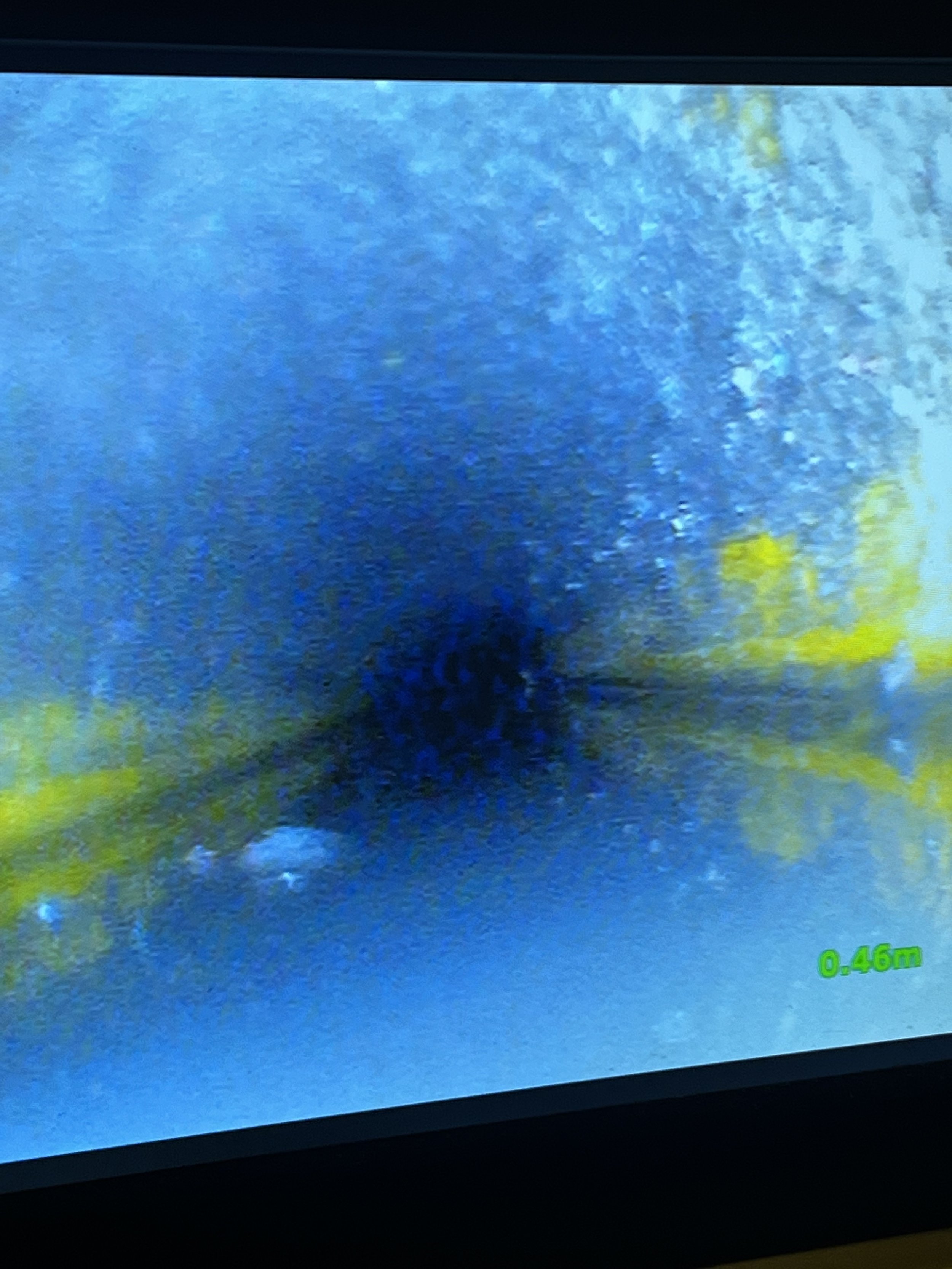

Wash Rooms

Commercial wash drainage pipe work de scales. milling of urinal pipe work to allow to full open bore. Wash room traps de scaled. Jetting off all wash room lateral pipe work to fully flood test.

-

Internal below Ground

Internal below ground man holes deep clean of man hole chambers & all connecting below ground to exiting interceptor & sump pits. Internal picote & mechanical wire cleans , internal jetting to flood test below ground pipe work.

-

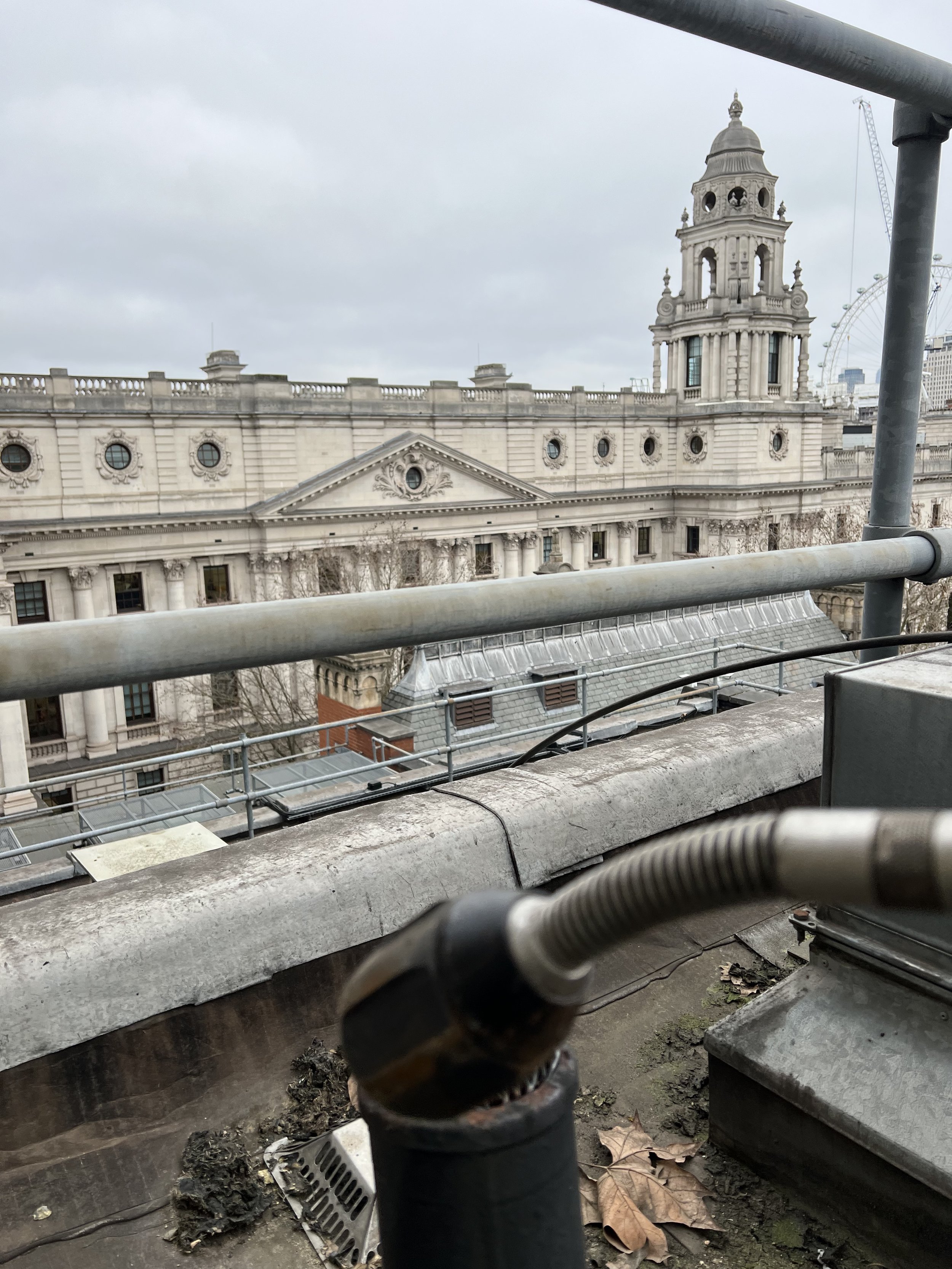

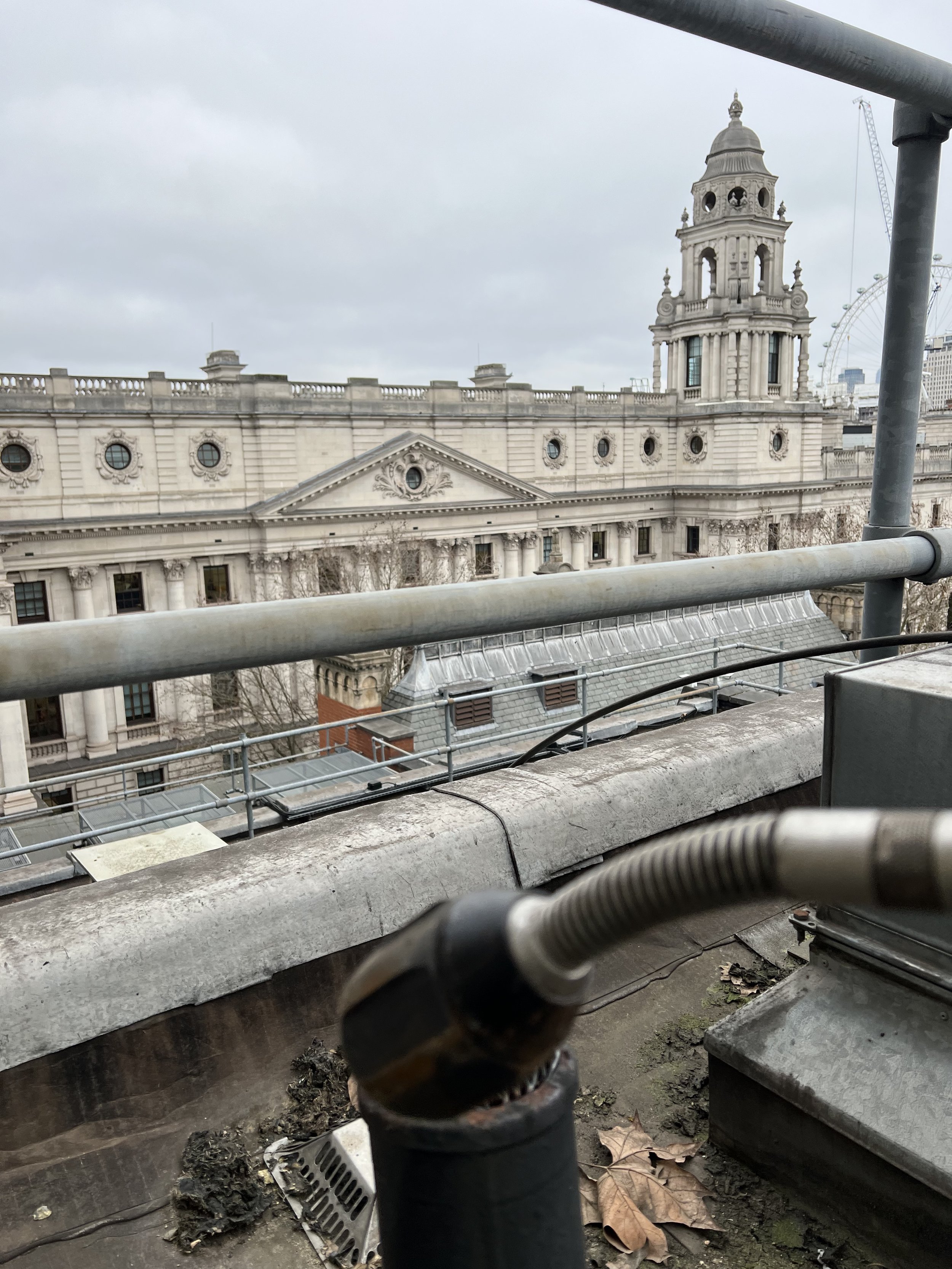

Main Roof Drainage

Main roof surface water inlets are cleaned of debris & flood tested to ensure surface water down pipes are fully operational. Gullies and roof surface jet washed & clean